Ergonomic testing

Designing a handle accessory

Design challenge

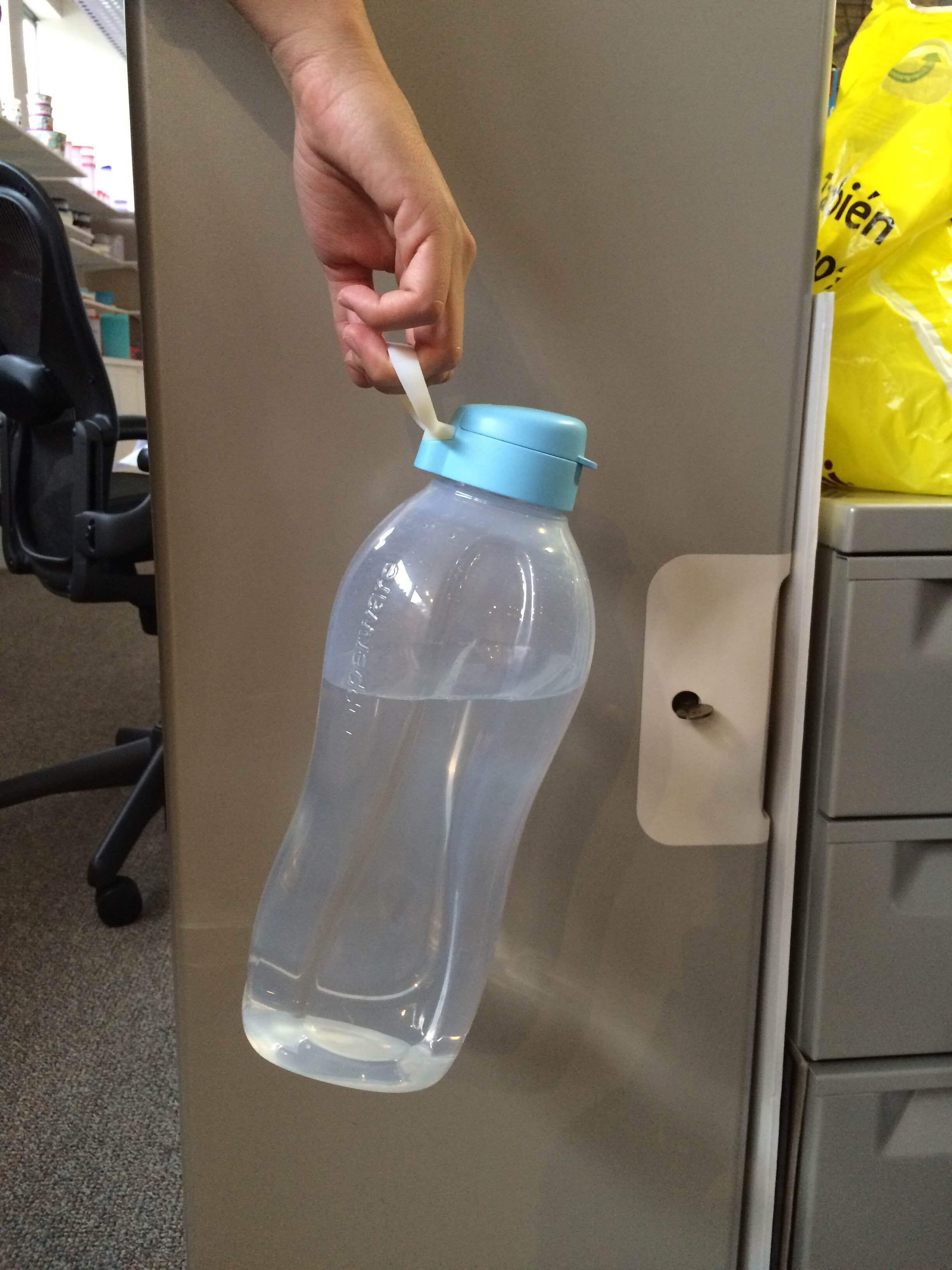

The 2 Liter Tupperware Eco Bottle is a popular choice for storing large portions of beverages for social events or even just daily use. The size of the bottle makes it difficult to grip though and sparked an opportunity to create a carrying accessory that provided a comfortable experience while carrying the bottle and pouring the contents.

Preliminary sketches exploring different carrying methods

Handmade and 3D printed prototypes used for testing ergonomics and surfacing methods

testing prototypes

As part of an internal test, 15 participants tested the comfort level of a 3D printed prototype. Each person carried a full-to-capacity 2L Eco Bottle for 10 minutes (average time it takes a person to travel 0.5 miles. They communicated any pain points that occurred and suggested potential solutions that could be used to solve the problem

Evaluating pouring

Evaluating carrying

Prototype evaluation sheets from 2 out of the 15 participants

implementing insights

After analyzing the evaluation sheets, three main insights were mentioned by the majority of the participants. “The thin edges are too sharp…”, “Handle is too small for the amount of weight…”, and “Only fit 3 fingers…seemed to cut off my circulation.” These comments directly influenced the changes made for the final design.

Changes implemented to improve the final design

1.) Make softer edges to remove pain points. 2.) Increase width for more finger room 3.) Add material to strengthen the handle

Final Design